A simple guide to key ordering times for your packaging.

Seasonal packaging always looks effortless on the shelf. Behind the scenes? It’s anything but last-minute.

At Clyde Presentation Packaging, we see the same pattern every year: the brands who plan early get better results — better materials, better finishes, better margins, and far less stress.

So, consider this your friendly nudge from your packaging partner.

If you’re planning packaging for 2026 launches, seasonal gifting, or limited editions, this guide will help you work backwards with confidence.

The Timelines

Here’s what a typical custom packaging journey looks like, but based on specific requirements, this might adapt slightly:

Brief Clyde

↓

Crafting proposal – ~1 week

↓

Refine detail & specification – ~4 weeks

↓

Plain sampling – 2–3 weeks

↓

Artwork development – ~1 week

↓

Printed sampling – ~4–5 weeks

↓

Final approvals – ~2 weeks

↓

Production & delivery – ~8–10 weeks

*Allow buffer for – internal sign-offs, freight contingencies, seasonal pressure

Average full project end-to-end lead time: 5-6 months

This timeline typically includes:

- Structural design & engineering

- Sampling and refinements

- Material sourcing (especially speciality papers)

- Manufacturing & finishing

- Freight and delivery

Packaging decisions made early unlock options. Late decisions can limit what can be achieved.

If you have a product for reprint or the packaging structure, finishing, agreed materials and artwork is ready to go then leadtimes would differ significantly. Speak to our expert sales team to learn more.

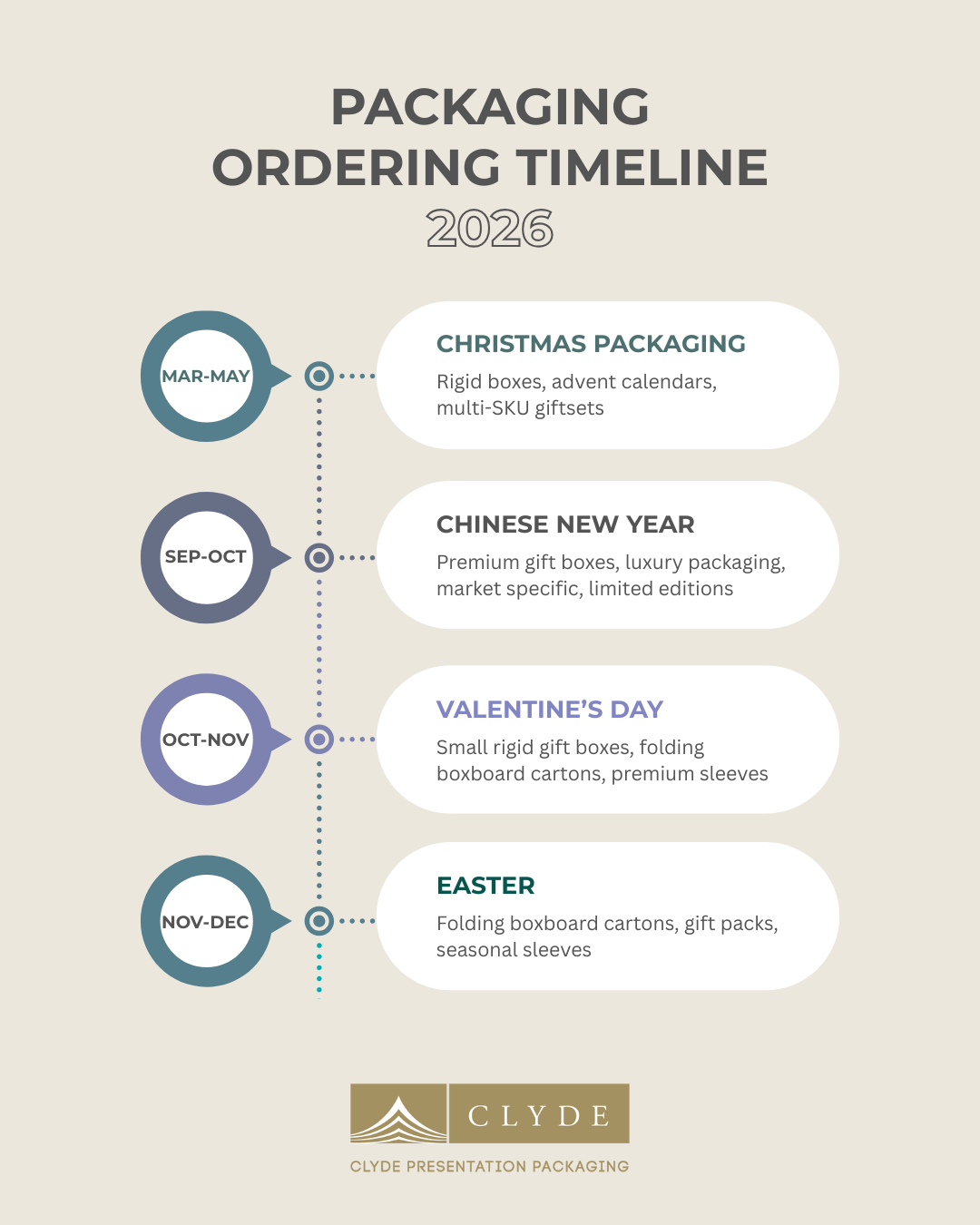

Key Seasonal Ordering Windows for 2026

Below are the realistic briefing windows we recommend if you want your packaging delivered on time — without compromise.

Christmas & Advent Calendars (December)

Brief by: March – May

Best suited for:

- Advent calendars (beauty, spirits, confectionery, wellness)

- Luxury rigid gift boxes

- Multi-SKU gift sets

- Bespoke inserts and complex internal structures

- Foil, embossing, debossing, specialty finishes

Christmas packaging is the most complex and highest-volume work of the year. Early planning allows for smarter structures, better materials, and fewer compromises later on. We always recommend getting products on-shelf by October/November to maximise those Christmas sales.

Chinese New Year (date varies)

Brief by: September – October

For international shipping brief by: August

Best suited for:

- Premium gifting boxes

- Spirits, beauty, food & luxury presentation packs

- Gold foils, bold colours, intricate detailing

- Limited-edition sleeves or cartons

Projects often involve detailed finishes and premium materials, which benefit from longer sampling and production timelines.

Valentine’s Day (February)

Brief by: October – November

Best suited for:

- Small rigid gift boxes

- Luxury folding cartons

- Premium sleeves

- Limited-edition colourways or finishes

Short-run seasonal packaging still needs time for material sourcing and finishing — especially when colour accuracy and texture matter.

Easter (March / April)

Brief by: November-December

Best suited for:

- Folding cartons and gift packs

- Seasonal sleeves and overlays

- Retail-ready packaging for limited editions

Easter often sits alongside core ranges. Planning early helps balance cost, consistency, and shelf impact.

Our Process

Good packaging is engineered, tested and refined. Rushing jobs can lead to issues down the line, which we aim to avoid at all costs.

Our process typically looks like:

- Brief & discovery

We understand your product, audience, budget, timelines, and retail requirements (see below for our full details of our post-consultation guide). - Structural design & specification

Box styles, inserts, materials, and finishes are engineered to protect and elevate your product. - Sampling

Plain samples first (structure and fit), followed by printed samples to refine finishes and colour. - Artwork & pre-press

Technical checks ensure artwork works on the material, not just on screen. - Production & finishing

Manufacturing, finishing, quality checks, and freight — all timed around seasonal demand.

The earlier we start, the more options you have at every stage.

Packaging Types WE SPECIALISE IN

Optimising your packaging planning for 2026 starts with knowing your options — so here’s a clear recap of our core packaging types and what they’re best used for.

Luxury Rigid Boxes

For premium gifting, cosmetics, home fragrance, spirits, and high-end retail.

Options include:

- Lift-off lid boxes

- Shoebox style

- Clam shell boxes

- Book box

- Magnetic closure boxes

- Hinged lid

- Shoulder box

- Exposed shoulder box

- Custom inserts (foam, EVA, card, moulded pulp)

- Finishes: foil, emboss/deboss, spot UV, soft-touch lamination.

E-Flute Boxes

Perfect for e-commerce, subscription boxes, retail mailers, and heavier products needing durability.

Benefits: lightweight, strong, excellent print finish, eco-friendly options available.

Wooden Boxes

With wooden boxes, there are plenty of options for customisation to truly tell your brand story. Closures, inserts, wood types are just the beginning. Let your creativity run wild!

Benefits: Strong, premium, perfect for gifting, highly customisable.

Folding Boxboard Cartons

Ideal for FMCG, cosmetics, confectionery, drinks, and smaller retail products.

Benefits: cost-effective, fast lead times, recyclable board options, high-quality print.

Bespoke Tubes

Great for spirits, beauty, home fragrance, food & drink gifting, and lifestyle brands.

Options: composite tubes, eco tubes, luxury finishes, foil accents, textured papers.

Branded Paper Bags

For retail stores, events, gift shops, farm shops, and boutiques.

Options: twisted handle, flat handle, luxury rope handle, kraft, coated, recycled papers.

Sustainable Packaging Options

Across all packaging types, we offer:

- FSC/PEFC-certified boards

- Recycled papers

- Plastic-free alternatives

- Moulded fibre inserts

- Mono-material solutions

If sustainability is part of your 2026 strategy (and it likely is), now’s the time to build it into your orders.

Understanding Your Packaging Requirements

Define Your Specific Needs:

To streamline the process as much as possible, before booking your free consultation with our sales team it’s always best to clearly outline your requirements:

- Product specifications: Size, shape, weight, and fragility of items (to choose the best insert required)

- Volume requirements: Current and projected order quantities

- Material preferences: Cardboard, biodegradable, or sustainable alternatives

- Branding requirements: Custom printing, colours, and design elements

- Budget: Cost per unit and total packaging spend

- Timeline expectations: Lead times and delivery schedules

When you plan early, you:

- Access better materials

- Secure production capacity

- Reduce last-minute costs

- Create packaging that truly reflects your brand

If you’re thinking about 2026 packaging, now is the time to start the conversation — even if the brief isn’t fully formed yet.

Want to Get Ahead of YOUR 2026 PROJECTS? Let’s Plan It Together.

Whether you need luxury rigid boxes, e-flute subscription packaging, printed cartons, sustainable tubes, or branded paper bags, we’re here to help you lock in your 2026 packaging strategy — calmly, clearly, and with no January surprises.

About Clyde Presentation Packaging

At Clyde Presentation Packaging, we’re proud to have collaborated with some of the world’s most prestigious brands, delivering high-end packaging designs to globally recognised names and smaller artisan brands.

Our portfolio includes an array of bespoke packaging solutions, from elegant engraved wooden cases to beautifully embossed and foiled bags and boxes, all crafted from the highest quality materials.

No matter the size of the project, each brief we receive is met with the same dedication to craftsmanship and creativity. Whether you’re looking for artisan packaging for a limited-edition collection or custom solutions for high-volume production, we’re here to transform your ideas into bespoke packaging experiences.